Flow-polymer is a black-oil polymer simulator in OPM, which is developed by extending the black-oil simulator Flow with a polymer component. The effects of the polymer mixing are simulated based on the Todd-Longstaff mixing model, and adsorption, dead pore space, and permeability reduction effects are also considered. A logarithmic shear thinning/thickening model is incorporated with the recent OPM Release 2015.10.

The following is a 3D example used to demonstrate the use of the polymer model. The data can be download from opm-data. To run the examples, just type the following command in the corresponding folders.

flow_polymer run.param

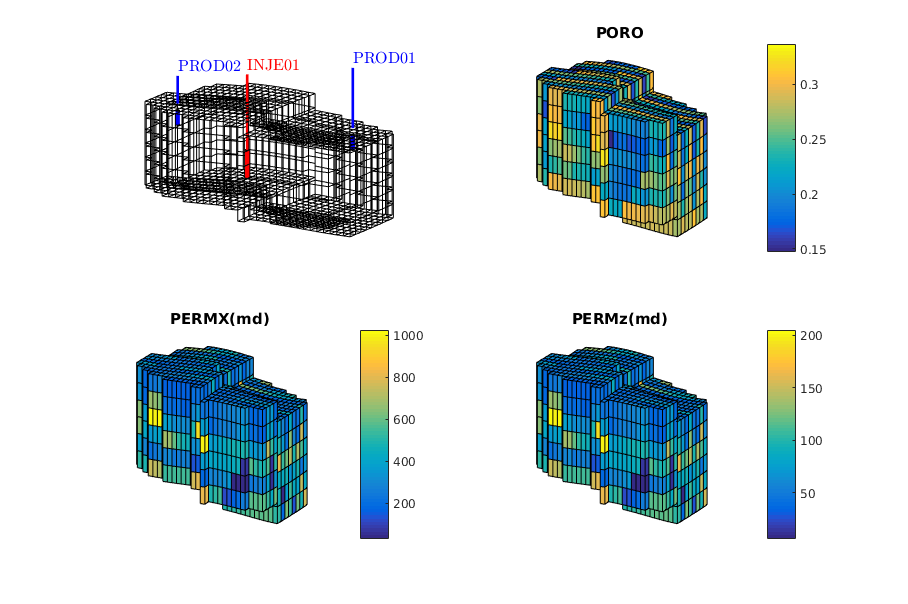

The following image show the configuration of example. It has two production wells in the top layers and one injection well in the bottom layers.

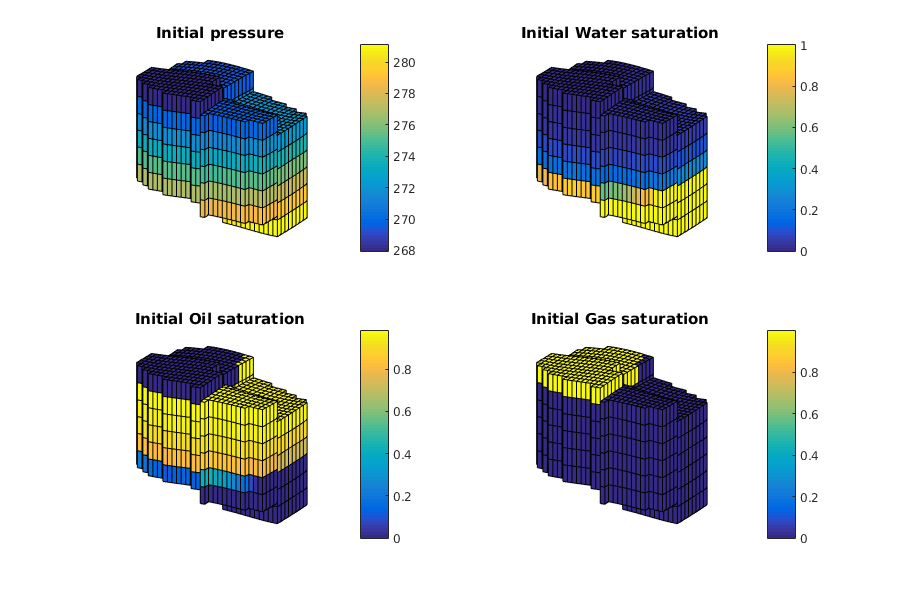

The following is the initial state of the example.

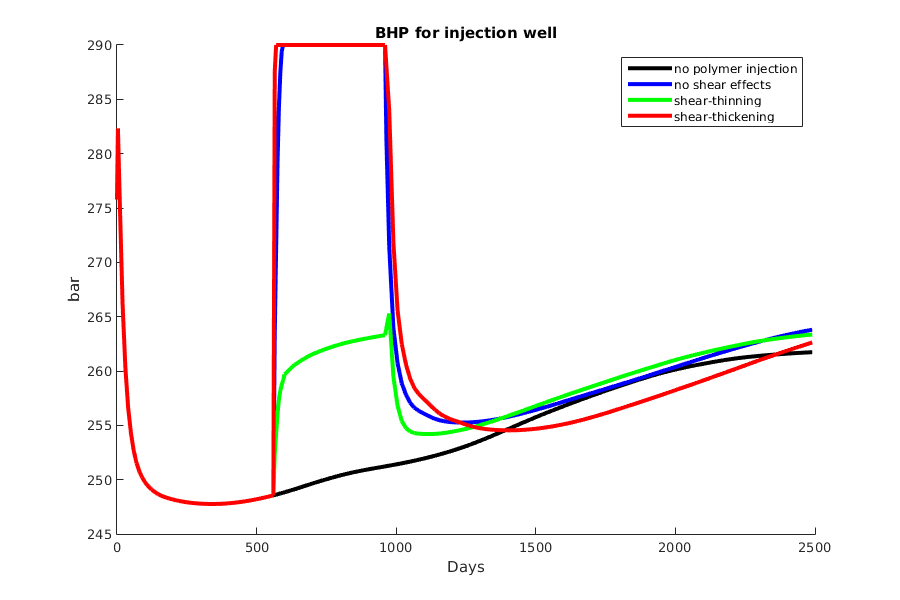

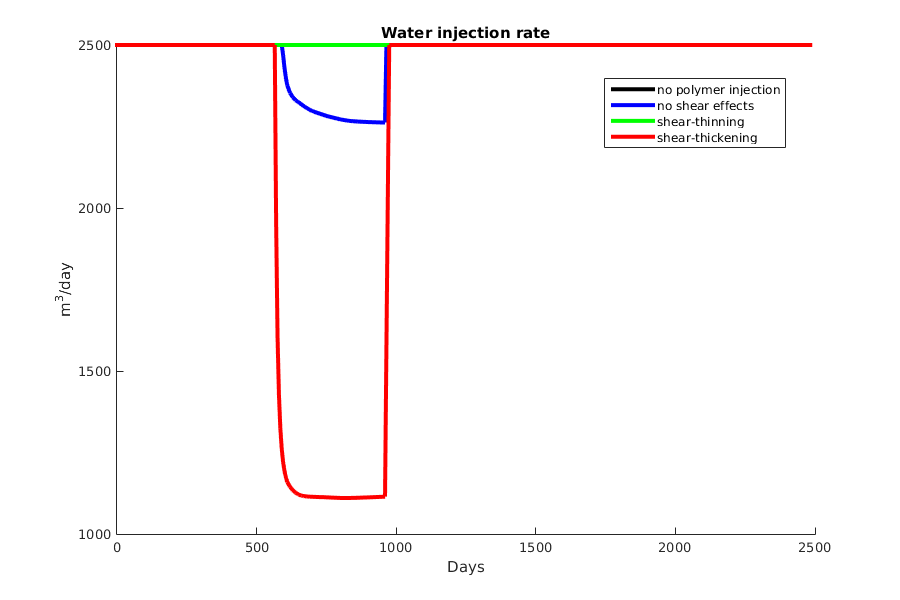

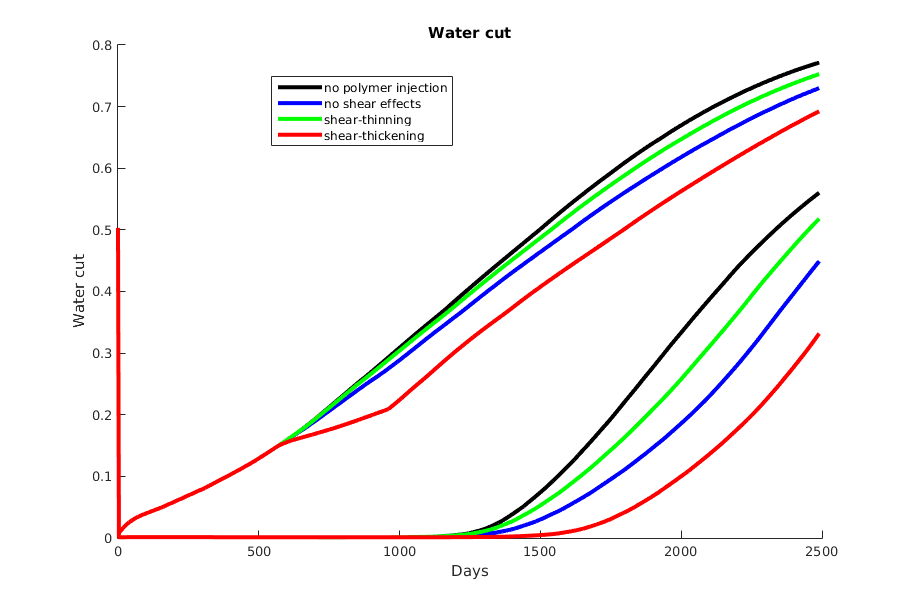

The flooding process begins with a 560-day pure water injection, then a 400-day polymer injection with concentration 1.0 kg/m^3. Finally, a 1530-day pure water injection is performed.

Four different kinds of configuration is used. The first one is that no polymer is injected, which is achieved by changing the polymer concentration to be 0 in the above flooding process. The second one is with polymer injection, while no shear effects are considered. The third one is with polymer injection and shear-thinning effects. The fourth one is with polymer injection and shear-thickening effects.

The following figures show the resulting evolution of bottom hole pressure and water injection rate for the injection well and the water cut for the production wells.